What Are Magnetic Rigid Boxes?

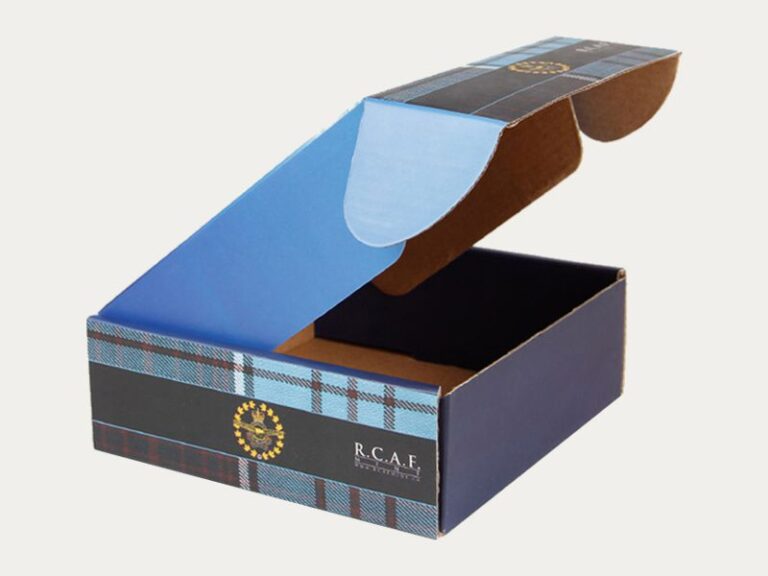

Magnetic rigid boxes are rigid boxes that feature a magnetic closure lid. They are a premium packaging solution intended for high-end products.

Reasons Why Brands Prefer Custom Magnetic Rigid Boxes

What follows is a list of reasons why custom magnetic rigid boxes are trending among the brands:

They Offer Better Protection

Custom magnetic rigid boxes are preferred by brands for their great functionality that offering better protection. The lids of these boxes snap shut on their own due to the magnet inside, which keeps the contents stored inside safe, regardless of where they’re being transported. Brands need durable packaging solutions to protect their products on the go. The best way to ensure durability is by choosing custom magnetic rigid boxes from a reputable supplier.

Custom Magnetic Rigid Boxes Can Offer Improved Functionality

The great functionality offered by custom magnetic rigid boxes makes them highly desirable in today’s market, where brands are looking for packaging solutions that offer improved performance and features. Brands have started using custom magnetic boxes in order to encourage their customers to properly dispose of the packaging, which means they have been forced to shift from using corrugated boxes and other solutions that did not offer the same level of functionality.

Custom Magnetic Rigid Boxes Are Trending For Their Aesthetics

Brands are opting for custom magnetic rigid boxes for reasons that go beyond functional value, and one of the primary reasons is their ability to support brand recognition. The boxes are printed with creative designs that match the company’s branding requirements; in fact, the design possibilities available for these boxes are endless due to their magnetized lids, which can easily be removed or replaced without causing any damage to the box itself.

They Offer Customizable Features

Brands are also looking for custom magnetic rigid boxes due to the customizable features that they offer, including unique shapes and sizes. The magnetic lids allow brands to choose from a wide range of size options when designing their boxes, ensuring that they can meet the packaging requirements for each product that they manufacture. The boxes are also available in various shapes, which means that brands can use them to promote their products creatively without compromising on functionality. Different types of businesses are using magnetic rigid boxes for very good reason – they help entice potential customers while offering a good customer experience.

Add-Ons For Magnetic Closure Rigid Boxes

If you want to create something truly unique when it comes to custom rigid boxes, we strongly recommend using add-ons. Some of the well-known add-ons are as follows:

Spot UV

Embossing

Debossing

Window Patching

Hot Stamping

Spot UV

The spot UV is mainly used to enhance the appearance of the product. It can give your packaging a very glossy or high-end look, which will definitely stand out in the market.

Embossing

An embossed box means that you are creating a three-dimensional effect on your rigid boxes. Embossing involves pressing patterns or designs into an otherwise flat surface, giving the product a three-dimensional look.

Debossing

It is the opposite of embossing and creates a recessed imprint onto your large and small rigid boxes.

Window Patching

You can also choose to use window patching on your custom boxes, which means that you can show your product through the windows.

Hot Stamping

Hot stamping is a way to add color and texture. It will provide an extremely luxurious look for your large and small custom rigid boxes. These are just some of the common add-ons used with rigid boxes, and if you want to find out more about these, feel free to reach out to Packaging Bee.

Finishing Coats For Stock Rigid Boxes

Do you want to add a layer of protection to your stock rigid boxes while improving their overall look? If yes, then you should check out finishing coats. Packaging Bee offers the following finishing coats:

Matte Finish

Gloss Finish

Varnish Finish

Soft-Touch Finish

Matte Finish

The matte finish is mainly used to reduce the shine on your stock rigid boxes.

Gloss Finish

A glossy finish can make your custom rigid boxes look very attractive. In addition, you can get a mirror-like appearance when opting for the gloss finish over an otherwise matte box.

Varnish Finish

The varnish finish is more resistant than the gloss and matte finish. It is perfect if you want to protect your box from scratches and dust.

Soft-Touch Finish

A soft-touch finish gives your stock boxes a velvety-like feel, which can be used for promotional purposes or creating an upscale feeling to your products

Printing Techniques For Custom Magnetic Rigid Boxes

Packaging Bee understands the importance of printing techniques and their role in bringing digital artwork to life. Therefore, we offer the following printing techniques:

Digital Printing Technique

Offset Printing Technique

Digital Printing Technique

This particular technique doesn’t require any setup and is cost-effective for low-volume orders. In addition, it offers good print quality and can cater to design changes without delays or additional costs.

Offset Printing Technique

On the other hand, sometimes good print quality just isn’t enough. Sometimes, you want the best possible print quality for your custom rigid boxes. That’s when you can opt for the offset printing technique. It offers exceptional print quality but is only cost-effective for high-volume orders.

Color Models For Custom Magnetic Rigid Boxes

Packaging Bee offers the following popular color models:

CMYK Color Model

PMS Color Model

When you get in touch with us, our packaging experts will help you make the right choice of color model based on your needs.

Ready To Place Your Order?

Packaging Bee offers custom magnetic boxes in custom shapes and sizes. Furthermore, we can craft them as per your needs while providing you with a myriad of customization options. In addition, we also offer different sampling options so that you can get a feel of the finished product. So, give us a call today, and let’s discuss how we can craft a custom packaging solution for your brand.

#p

| Dimensions |

All Custom Sizes & Shapes |

| Printing |

CMYK, PMS, No Printing |

| Paper Stock |

10pt to 28pt (60lb to 400lb) Eco-Friendly Kraft, E-flute Corrugated, Bux Board, Cardstock |

| Quantities |

100 – 500,000 |

| Coating |

Gloss, Matte, Spot UV |

| Default Process |

Die Cutting, Gluing, Scoring, Perforation |

| Options |

Custom Window Cut Out, Gold/Silver Foiling, Embossing, Raised Ink, PVC Sheet. |

| Proof |

Flat View, 3D Mock-up, Physical Sampling (On request) |

| Turn Around Time |

4-6 Business Days, Rush |